Better Data Drives Better Action, But Urgency Matters and Requires the Right Science and Technologies

In the asset-heavy industries, asset managers know that better data leads to better decisions. But here’s the reality: waiting for perfect data is costing millions. Infrastructure is aging, ESG pressures are intensifying, and operational risks are growing. The question isn’t whether you have enough data—it’s whether you can act on it fast enough.

The Competitive Edge: Science Meets Urgency

“Never let perfect get in the way of good. I am, of course, in favor of improving data quality over time… but you can’t wait. You can’t wait for tomorrow to deal with today’s problems,” says Dr. Ian Oppermann, Chair, Global Advisory Board, KartaSoft.

KartaSoft’s unique physics-informed AI model changes the game. Unlike traditional machine learning models that falter with messy, incomplete datasets, KartaSoft transforms the asset management landscape with grounded engineering principles and robust data-driven algorithms.

The result? Models that understand the physical realities of pipelines, compressors, and other critical assets—delivering insights with an extremely high degree of accuracy even when data is far from perfect.

Bridging the Gap Between Data and Decisions

KartaSoft technology is designed to bridge the gap between data and analytics, enabling operators to make faster, fact-based decisions. Our partners are now leveraging:

✔ Unified frameworks for aging networks—something previously thought impossible.

✔ Outputs that empower engineers and operations teams to make fact-based decisions.

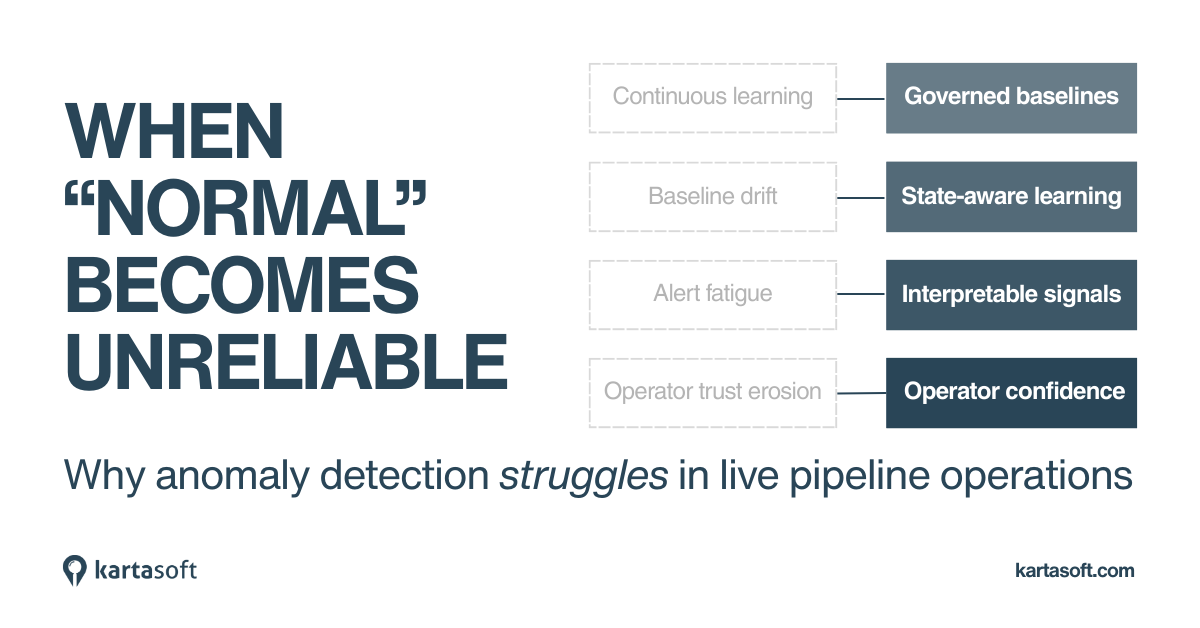

✔ Risk and anomaly detection with exceptional accuracy, long before leading indicators.

“Predicting failures months ahead changes the economics of maintenance,” explains David Cleminson, KartaSoft CTO.

“Instead of reactive schedules, asset managers can prioritize interventions where they matter most—saving millions and reducing downtime.”

Evidence in Action

Consider a gas pipeline network spanning 147,000 miles. Traditionally, maintenance teams rely on scheduled inspections or sensor alerts—often reacting after degradation has already occurred. With physics-informed AI, operators can predict anomalies 3–6 months before leading indicators appear, enabling targeted maintenance and avoiding costly emergency repairs.

The impact is profound:

- Maintenance budgets are optimized for capital planning programs through reliability-centered strategies.

- Asset lifespan extended, maximizing capital efficiency.

- ESG compliance improved, as predictive insights help prevent leaks and environmental incidents.

Why Urgency Matters

Every day of delay increases the risk.

KartaSoft technology isn’t just a technology upgrade or hypothetical, we are supporting Fortune 500 companies to stay ahead of operational, financial, and regulatory challenges.

Take the Next Step

Gold-standard data is rare. Waiting for it is costly. The future belongs to those who act now.

Watch Energy Equation EP1 to learn why physics-informed AI is redefining predictive maintenance for oil and gas:

.jpg?width=750&height=422&name=Blog%20feature%20image%20(5).jpg)

.jpg)

.jpg)

.jpg)